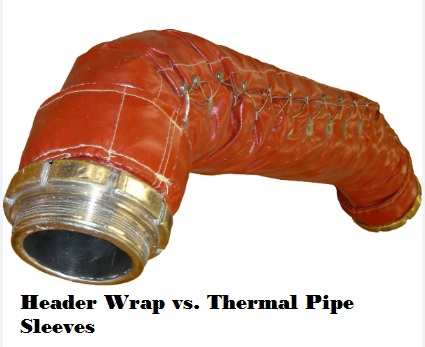

In many different applications, from automobile engineering to industrial systems, heat control is crucial. Thermal pipe sleeves and header wrap are two frequently used heat control techniques. While these products all aim to regulate temperature, their uses and advantages are different. This thorough tutorial will examine the main distinctions between header wrap and thermal pipe sleeves, assisting you in making an informed choice based on your own requirements.

Header Wrap: Heat Control in Automotive Engines

In the automotive industry, Header Wrap is a specialized heat-resistant material used mostly in exhaust systems. Its main function is to contain and insulate heat from exhaust headers. The header wrap efficiently controls the heat within the exhaust system by encasing the headers in this specially designed tape or cloth. This procedure improves exhaust gas flow and reduces heat loss into the engine compartment.

Benefits of Header wrapping

- Performance Enhancement: By maintaining the ideal exhaust gas velocity and minimizing heat transfer to neighboring components. Header wrap can result in a substantial improvement in horsepower and torque.

- Engine Bay Temperature Reduction: Header wrap helps keep the engine bay cooler by keeping heat within the exhaust system. It improves overall engine performance.

- Header wrap assists in preventing heat-related damage to neighboring components, such as wire and hoses. This can increase the lifespan of these important elements.

Thermal Sleeves: Piping System Protection

In contrast, Thermal Pipe Sleeves have a specific function because they are made to protect piping systems. From extremely hot or cold temperatures. To stop heat loss or condensation, these sleeves are frequently used in industrial settings and HVAC (heating, ventilation, and air conditioning) systems. Thermoplastic pipe sleeves, which are available in a variety of materials including foam, fiberglass, and rubber, provide differing degrees of insulation to meet different needs.

Advantages: Thermal Pipe Sleeves

Thermal pipe sleeves provide insulation for pipes, ensuring that fluids keep their desired temperature during transit and maximizing system performance. This considerably reduces energy waste.

- Control of condensation: In cold areas, thermal pipe sleeves stop pipes from condensing. In addition to preventing corrosion, this improves the system’s overall effectiveness.

- Physical barrier: Thermal pipe sleeves serve as a physical barrier that protects pipes from outside influences and potential harm in addition to providing insulation.

Installation and Maintenance

When considering header wrap and thermal pipe sleeves for your heat management requirements, proper installation and maintenance are essential.

- Installation of header wrap: Header wrap installation entails carefully wrapping heat-resistant material around the exhaust headers or pipes. To ensure its efficiency, it must be securely fastened in place. Its performance may be maintained with regular examination and retightening, especially following the initial heat cycles.

- Header Wrap Upkeep: Regular inspections are required to look for signs of wear, tear, or damage. It’s crucial to replace the header wrap right away if you see any signs of wear or fraying. Additionally, maintaining the wrap clean and clear of dirt or oil accumulation helps extend its lifespan and ensure that it continues to offer the best possible heat regulation.

- Installation of Thermal Pipe Sleeves: To install thermal pipe sleeves, place them tightly over the pipes you want to insulate. Make sure the item fits snugly and properly, and follow any manufacturer’s recommendations.

- Thermal pipe sleeve maintenance involves checking them periodically for wear or damage. To preserve their insulating qualities, think about replacing them if you observe any compression or wear. Cleaning the sleeves on a regular basis can stop the accumulation of impurities that could harm their efficiency.

You can maximize the advantages of header wrap and thermal pipe sleeves and ensure they properly fulfill their intended functions by understanding the proper installation processes and putting them into practice.

Selecting Best Option

The exact requirements of your project or application will determine whether to use thermal pipe sleeves or header wrap. Header wrap is the best option if you’re working on an automotive project that aims to improve exhaust system performance while also lowering underhood temperatures. Header wrap can result in considerable performance gains because it is specifically designed for containing and managing heat within the exhaust system.

The goal of pipe insulation, on the other hand, is to improve energy efficiency and prevent condensation in industrial or HVAC systems. The best option is thermal pipe sleeves. These sleeves provide the protection and insulation that your piping system needs to maintain stable temperatures.

Conclusion

Thermal pipe sleeves and header wrap are both essential instruments for managing heat, but they have different uses. Think carefully about the particular needs of your project in order to make an informed choice and make sure you are using the right solution. A wise decision between header wrap and thermal pipe sleeves can be the difference between success and failure, whether the goal is to optimize automobile performance or increase energy efficiency in industrial applications.